Plants for furniture processing

Machines and plants for competitive furniture production were the starting point for the Homag Group of companies, and to this day represent a hinge pin of the Group´s overall product policy.

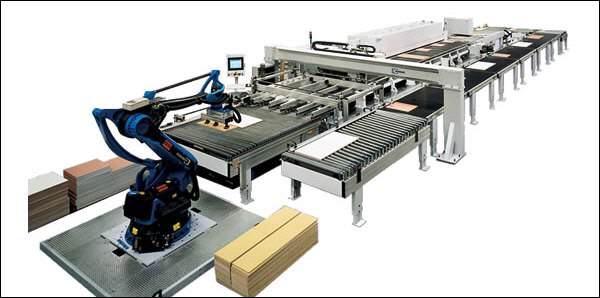

The Homag Group is able to cover almost the entire process chain of furniture production with its own, innovative products - from panel sizing through to packaging. The wide range of technical solutions offered stretches from just-in-time production of batch sizes 1 through to high-performance volume production.

Of ever increasing significance in this process is the integration of machines and plants into superior information and communication systems. Here, too, the Homag Group´s open control system offers the ideal platform.

Key furniture production processes using Homag Group technology:

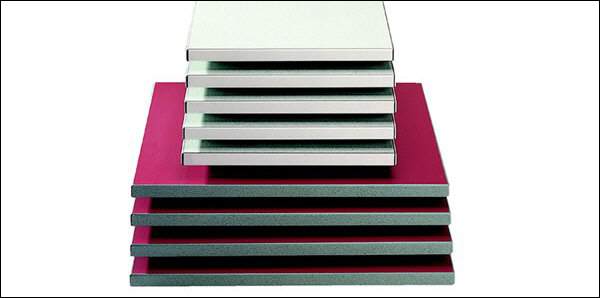

- Panel cutting

- Surface coating

- Sizing and edge processing

- Drilling and routing processes

- Assembly

- Packaging

- Storage, handling and order picking

As versatile and flexible as you are:

Whatever furniture components you produce - whether kitchen, bathroom, office, living room, bedroom or study furniture, whether assembled or flat packed, based on individual customer or in high volumes, whether melamine, veneer or solid wood - Homag Engeneering will find the taylor-made solution to meet your specific application requirements.

(C) 2007 ATEL international /Germany - All rights reserved